|

|

|

|

|

|

|

|

| System Includes: |

|

| 36,000 BTU Indoor Unit (Air Handler)

36,000 BTU Outdoor Unit (Condenser)

INVERTER TECHNOLOGY - 16 SEER / 8.2 HSPF

Operates in Ambient Temps down to -22F!!

15ft lineset/15ft wire included.

Extend linesets & wire using dropdown menu

1 Year Part / 5 Year Compressor Warranty |

|

|

|

|

|

|

|

|

|

| Top Line Features: |

|

Maximum Efficiency: 16 SEER DC Inverter Technology

Pre-Charged with Eco-friendly R-410a Refrigerant

Most Powerful Single Zone Output on the Market!

36,000 BTU's of Turbo Cooling and Heating

Operates in Ambient Temps down to -22F!!

Vertical Swing distributes air evenly throughout space

Mitsubishi Compressor - Powered by GREE

Sleep Mode - 24 hour ON/OFF Timer - Memories.

Auto & 3-Speed Fan Control with 24 Hour Timer

Perfect for Greenhouses / Server Rooms. |

|

|

|

|

|

|

|

Model Number |

T316HHS-H236 |

Compressor |

Mitsubishi |

Refrigerant / Pre-Charge |

R410A / 119.9oz - 25ft lineset |

Cooling Capacity |

36,000 BTU / (7400 - 36000 BTU) |

Heating Capacity |

36,000 BTU / (15,000 - 36000 BTU) |

Air Flow (H-M-L) |

824 / 706 / 677 CFM |

Power Supply |

230 V / 60 Hz, 1Ph |

Input Power |

4235W (cooling) / 3835W (heating) |

Input Current (Rated) |

18.5A (Cooling) / 16.7A (heating) |

SEER |

16 |

EER |

8.5 |

HSPF4 |

10.0 |

Maximum Fuse |

40A |

Sound Level (H-M-L) |

53.5 / 42 / 38.5 (indoor) - 60dB (outdoor) |

Min Operating Temperature |

- 15 C / 5 F |

Lineset Size (Liquid x Gas) |

3/8" x 5/8" |

Maximum Lineset Run |

125ft |

Maximum Elevation |

33ft |

Gross Weight |

43.2 Lbs (Indoor) / 136.7 Lbs (Outdoor) |

Dimensions (WXDXH) |

49.6 x 10 x 11.1 x 14.25 in (Indoor Unit) – 37.3 x 16.55 x 31.9 in (Outdoor Unit) |

Warranty |

1 Year on Parts / 5 Years on Compressor |

| Click to View Full T316S-H236 Specification Sheet >>> |

|

|

|

|

|

|

|

| WHAT IS DC INVERTER? |

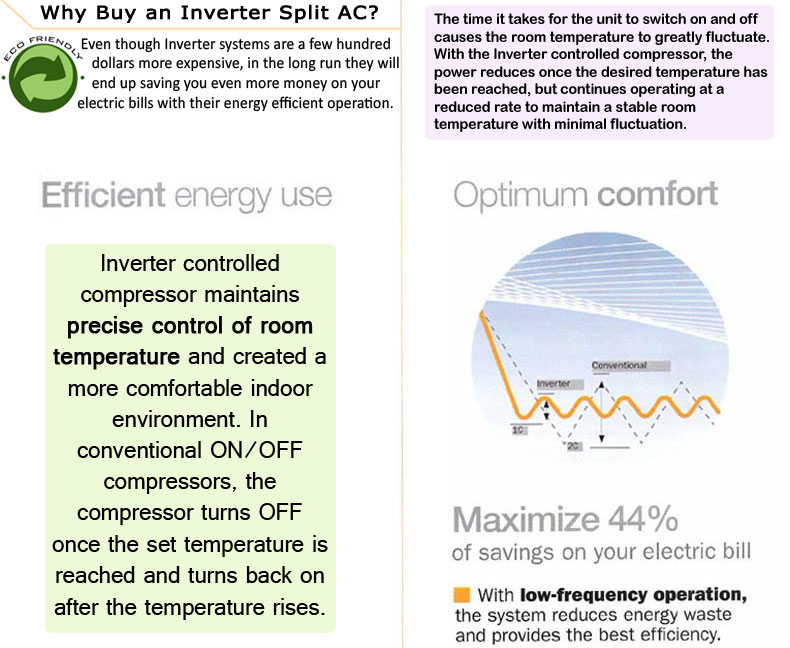

DC Inverter Air Conditioners are the ultimate cooling and heating technology of the HVAC field. They are called "DC inverter" because the alternative current (AC) is converted to Direct Current (DC) then, direct current inverted back to Alternative current with desired frequency. As known, the current supplied through the wall outlet has fixed frequency which is 60 Hertz. Different frequencies supplied to the compressor will result different running speeds of the compressor. Inverter control systems use Pulse Amplitude Modulation (PAM) that is the most advanced and energy efficient method of inverting the current. DC Inverter air conditioners bear special compressors that their speed could be changed by increasing or decreasing the frequency of the supplied power. Therefore, unlike conventional split Air Conditioners/Heat Pumps which cycle between on and off repeatedly, the DC Inverter control system will monitor the room temperature and adjust the compressor speed automatically.

Conventional compressors turn on and off to maintain the room temperature at desired level. This will result compressor to draw tremendous energy each time it starts up. This will also reduce the life-span of the compressor and other components that are turning on and off. Once a conventional system is running, it runs at its maximum speed, consuming the maximum amount of energy in order to produce the maximum of cooling or heating to maintain the desired temperature. The system will then cycle between on and off in an effort to maintain this temperature. When a DC Inverter compressor initially starts up, it runs with a higher speed to bring the room temperature to desired level rapidly. Once the set temperature is reached, it slows down and adjust its capacity to counter the heat loss or heat gain of the building. By this way it will maintain a constant temperature. |

|

|

|

|

|

|

|

|

|

| Install Kit Contents: |

|

|

15 Ft Flared Copper Tubing

15 Ft Pipe Insulation

|

|

|

Drain Pipe (indoor)

Wall Bracket for Indoor Unit

Plastic Pipe Wrap

|

|

|

|

|

Installation and User Manual

Neoprene Putty to Seal Holes

|

|

|

|

|

|

|

|

|

|

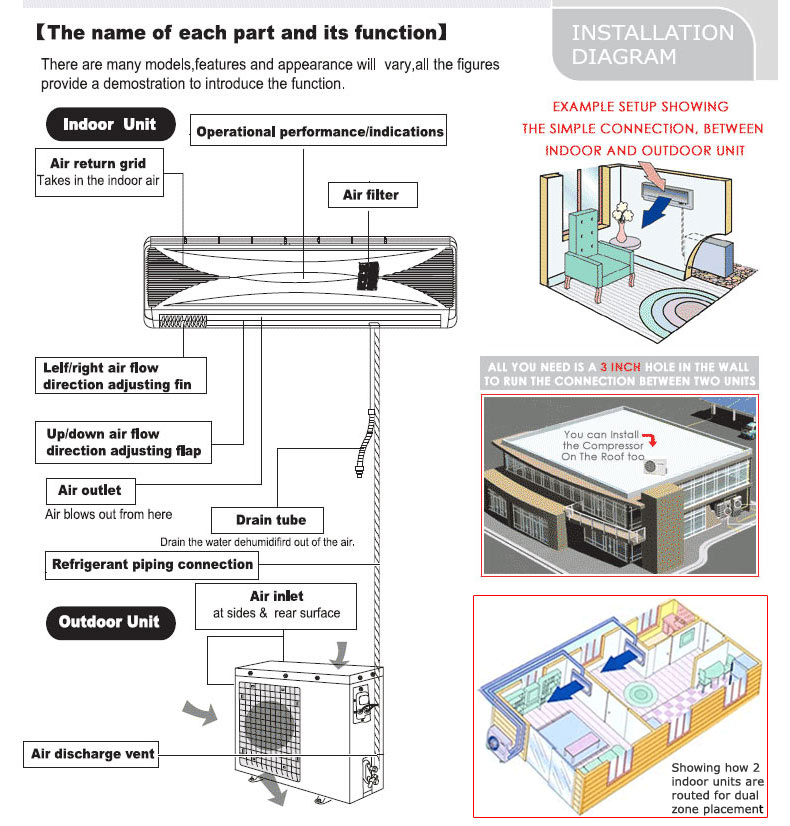

| BASIC OVERVIEW: The indoor unit is hung like a picture frame approximately 6 - 8 feet above the floor usually on an exterior wall. A 2-3 inch hole must be made behind the indoor unit in the exterior wall to run the refrigerant copper tubing, electrical wires and the condensate drain to the outside unit. The indoor unit and outdoor unit are connected to each other by means of refrigerant copper tubing and electrical cables. The condensing unit comes pre-charged with Freon however, the lines still need to be vacuumed to evacuate the excess Nitrogen prior to the final coupling for operation. Click to Download Installation Manual. *Although the installation may seem easy to some, certain tools and experience is necessary to complete installation of a mini split* See Installation Tip. A certified HVAC technician must conduct / complete the installation to be eligible for the warranty. (See warranty details below > ) |

|

|

|

|

|

|

|

|

|

|

| *5 Year Compressor - 1 Year on all other Parts* Registration card will be sent with unit, this card should be completed by an HVAC technician (installer). Installation of a mini split must be completed by a licensed HVAC (Heating, ventilating, & air conditioning) company to ensure any issues encountered in the future are not due to improper installation / workmanship. Even though mini split setup is below the expertise requirements of central AC systems, these are not "plug-n-play" units that can be properly installed without certain tools any prior HVAC - electrical knowledge. The installation includes electrical, gas, and refrigerant connections and generally regulated by a multiple sets of laws, codes and guidelines, at the federal, state and local levels. The failure to properly install HVAC equipment can raise personal safety and performance concerns. Warranty service - troubleshooting is provided through the contractor / installer and will be upheld as long as policies are observed. Once a non-defective unit is installed by a HVAC company, chances of anything going wrong are very slim and almost all contractors will guarantee there workmanship and provide future service free of charge (installation warranty). If it was determined that the unit is not functioning due to a defect and needs to be replaced, the part will be sent free of charge up to 1 year from date of purchase or 5 years for the compressor. If you receive a damaged or defective product, a replacement unit will be sent out Free of cost. Damaged / Defective product will be picked up and brand new exchange will be shipped out. Download Manual - Warranty Polices > |

|

|

|

|

|

|

SHIPS TO TO BOTH UNITED STATES AND CANADIAN LOCATIONS! |

|

|

|

|

| Our Thermocore systems ship via RL Carriers or similar LTL freight service out of Oak Park, Michigan and are palletized onto a single skid. Transit time is usually between 4 to 6 business days from payment receipt depending on where you are geographically located. Please provide a contact phone# upon checkout (to be used for delivery purposes only). SOMEBODY MUST BE ON SITE TO ACCEPT / SIGN FOR Order. Failure to provide valid contact# will delay order. System comes with Free shipping - this includes delivery to any location within the Continental United States. We will ship to Canadian locations but we need to quote separately - please contact our offices. Additional freight for Canadian registries is usually around $150. (import and duties may apply). |

|

|

|

|

|

|

|

|

|

| |

|

|